Available In:

- Diesel

- Electric

400 HP

Max Horsepower

Available In:

400 HP

Max Horsepower

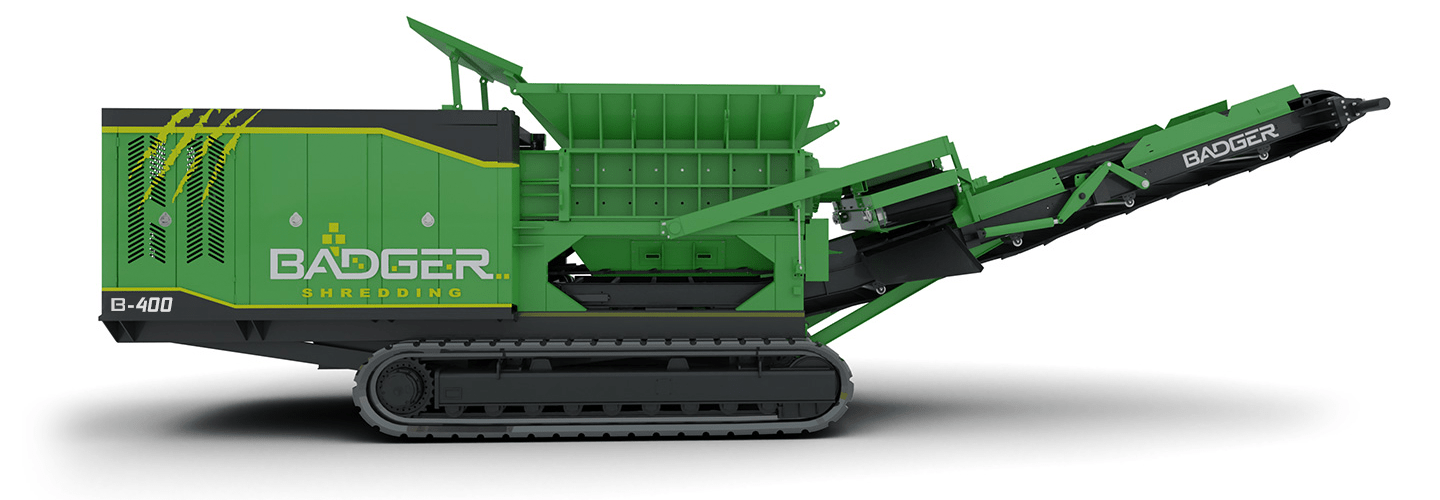

Built with the same rugged durability and superior twin-shaft shredder design used by its big brother, the B-400 features 400 hp of reliable shredding power in your choice of electric or diesel power. The Badger’s unique shredder design avoids jams and can quickly be converted to refine almost any material – concrete to demo materials to scrap metal. Featuring all-new technological features and our exclusive replaceable shaft tips, the Badger’s components are designed for maximum life, low maintenance, and reliable operation in any condition.

Available In:

400 HP

Max Horsepower

Built with the same rugged durability and superior twin-shaft shredder design used by its big brother, the B-400 features 400 hp of reliable shredding power in your choice of electric or diesel power. The Badger’s unique shredder design avoids jams and can quickly be converted to refine almost any material – concrete to demo materials to scrap metal. Featuring all-new technological features and our exclusive replaceable shaft tips, the Badger’s components are designed for maximum life, low maintenance, and reliable operation in any condition.

| Engine | Volvo D11 Stage IV / Tier 4F | 400HP |

| Standard Shredding Chamber dimensions | 56″ x 60″ |

| No. of Shafts | 2 each |

| Standard Number of Blades per Shaft | 8 per shaft |

| Cutting elements per blade | 2 each |

| Shaft/Blade RPM | 12 – 17 RPM |

| Machine Length in Operating mode | 44′ |

| Width of Belt | 48″ |

| Dumping Height | 10′ |

| Overall Unit Height | 11’ 3” |

| Overall Unit Width | 10’ 4” |

Badger pioneered the ability for operators to replace and/or reconfigure their blade shafts for any shredding need. That’s versatility others can’t touch.

The Badger’s unique shredding action produces less airborne particles than competitive designs. Reducing worker exposure to unhealthy and sometimes toxic airborne particles is an important preventative measure.

The Badger’s oversized hopper increases capacity and throughput, creating greater job site efficiency and reducing the need to double handle materials.

Available with a permanent self-cleaning high-strength magnet, the Badger’s separation system efficiently removes steel (or ferrous) material from the debris and is adjustable for your job site needs.

See why customers ask for us by name

Badgers are tested and proven in real-world conditions and harsh extremes.

Engineered to provide unmatched shredding performance your jobsite can rely on.

Manufactured in the USA to deliver superior production advantages & greater ROI.

Changing the way the industry applies heavy equipment technology - from efficiency to safety.

The Badger twin shaft, slow speed, high torque shredding machine represents a new evolution in recycling. By incorporating innovative new-to-market features and benefits, Badger has the versatility to shred more types and sizes of materials than anyone else.